|

Need help finding machinery? Submit a Request » |

-

Industrial Dust Collectors

-

Tube Benders / Tube End Formers

-

Metal Working Machinery

- New Arrivals Recently Sold Login About Testimonials Inventory Careers Contact AirMax Filters TubeMax

Fabrication MachineryWelding MachinerySawsPresses & RivetersPress Brakes/ShearsIronworkersRoll Bending/FormingChip ProcessingChip WringersCoolant Filter SystemsChip Crushers/ShreddersUsed Puck and Briquette MachinesView All Chip ProcessingCleaning & FinishingParts WashersBlast MachinesBelt Sanding/FinishingView All Cleaning & FinishingView All Metal Working

BendersCNC Tube Benders/CNC Pipe BendersTube Benders/Pipe BendersRefurbished BendersBendPro MachinesPines Tube BendersVertical Tube BendersEnd FormingTube End Flaring & Beading MachinesTube End FinishersTube End FormersCrimping MachinesTube Branching & Collaring MachinesTube Closing MachinesMore Tube Forming & ResourcesTube Cut-OffsMuffler MachineryTube MillsTube Punching & Perforating MachinesTooling & Repair PartsTools & DownloadsView All Tube Forming -

Metal Working Machinery

AccessoriesAirMax Replacement BlowersAirMax Replacement FiltersTools & DownloadsBooth & Backdraft View All Dust Collectors -

Tube Benders / Tube End Formers

-

Industrial Dust Collectors

-

Tube Benders / Tube End Formers

-

Metal Working Machinery

- New Arrivals Recently Sold Login About Testimonials Inventory Careers Contact AirMax Filters TubeMax

Fabrication MachineryWelding MachinerySawsPresses & RivetersPress Brakes/ShearsIronworkersRoll Bending/FormingChip ProcessingChip WringersCoolant Filter SystemsChip Crushers/ShreddersUsed Puck and Briquette MachinesView All Chip ProcessingCleaning & FinishingParts WashersBlast MachinesBelt Sanding/FinishingView All Cleaning & FinishingView All Metal Working

BendersCNC Tube Benders/CNC Pipe BendersTube Benders/Pipe BendersRefurbished BendersBendPro MachinesPines Tube BendersVertical Tube BendersEnd FormingTube End Flaring & Beading MachinesTube End FinishersTube End FormersCrimping MachinesTube Branching & Collaring MachinesTube Closing MachinesMore Tube Forming & ResourcesTube Cut-OffsMuffler MachineryTube MillsTube Punching & Perforating MachinesTooling & Repair PartsTools & DownloadsView All Tube Forming -

Metal Working Machinery

AccessoriesAirMax Replacement BlowersAirMax Replacement FiltersTools & DownloadsBooth & Backdraft View All Dust CollectorsCFM versus Horsepower – Why Does This Ratio Matter?

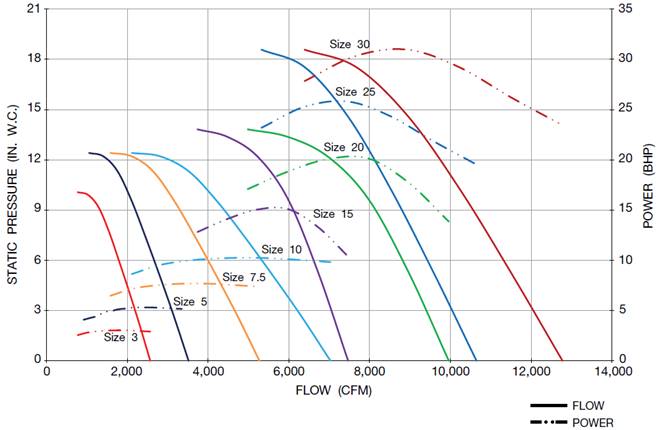

CFM, or cubic feet per minute, is used to measure the rate at which air is moving. Horsepower (HP) is used to measure the power of the blower in a dust collection unit. This ratio of CFM versus horsepower is important, since the goal is to get the ideal CFM with the lowest horsepower to save on energy costs.

In dust collection, you must also factor in static pressure (SP). Static pressure is the resistance to flow measured in inches of water (wc). To move a given amount of CFM, the fan requires a certain amount of horsepower to move the air at a given static pressure.

For example, say you know that you need 6,000 cfm at 6" of static pressure for a CNC molder machine. Due to the loss of friction through ductwork and the dust collection system, you add another 4" of static pressure, making a total of 10" of static pressure. Based on that, you need to move 6,000 cfm at 10”.

Using the diagram below, you can determine what horsepower the most efficient blower needs to be to get your ideal CFM. Apply this information as you browse our selection of Industrial Dust Collectors to find the right fit for your needs.

After reading this performance curve, a size 15 HP blower is going to get you 5,900 cfm at 10” SP. You know that you are maxing out the motor so there is no wasted energy.

Have more questions about CFM, horsepower, and static pressure? Call AM Industrial Machinery today at 216-433-7171.

Home | Blog | About | Testimonials | Inventory | Export | Careers | Contact | AirMax | Login | Sitemap | Privacy Policy | Terms & Conditions | LocationAll Rights Reserved 2025, AM Industrial Group, LLC - Admin Login

Web Development by Alt Media Studios -

Tube Benders / Tube End Formers