|

Need help finding machinery? Submit a Request » |

-

Industrial Dust Collectors

-

Tube Benders / Tube End Formers

-

Metal Working Machinery

- New Arrivals Recently Sold Login About Testimonials Inventory Careers Contact AirMax Filters TubeMax

Fabrication MachineryWelding MachinerySawsPresses & RivetersPress Brakes/ShearsIronworkersRoll Bending/FormingChip ProcessingChip WringersCoolant Filter SystemsChip Crushers/ShreddersUsed Puck and Briquette MachinesView All Chip ProcessingCleaning & FinishingParts WashersBlast MachinesBelt Sanding/FinishingView All Cleaning & FinishingView All Metal Working

BendersCNC Tube Benders/CNC Pipe BendersTube Benders/Pipe BendersRefurbished BendersBendPro MachinesPines Tube BendersVertical Tube BendersEnd FormingTube End Flaring & Beading MachinesTube End FinishersTube End FormersCrimping MachinesTube Branching & Collaring MachinesTube Closing MachinesMore Tube Forming & ResourcesTube Cut-OffsMuffler MachineryTube MillsTube Punching & Perforating MachinesTooling & Repair PartsTools & DownloadsView All Tube Forming -

Metal Working Machinery

AccessoriesAirMax Replacement BlowersAirMax Replacement FiltersTools & DownloadsBooth & Backdraft View All Dust Collectors -

Tube Benders / Tube End Formers

-

Industrial Dust Collectors

-

Tube Benders / Tube End Formers

-

Metal Working Machinery

- New Arrivals Recently Sold Login About Testimonials Inventory Careers Contact AirMax Filters TubeMax

Fabrication MachineryWelding MachinerySawsPresses & RivetersPress Brakes/ShearsIronworkersRoll Bending/FormingChip ProcessingChip WringersCoolant Filter SystemsChip Crushers/ShreddersUsed Puck and Briquette MachinesView All Chip ProcessingCleaning & FinishingParts WashersBlast MachinesBelt Sanding/FinishingView All Cleaning & FinishingView All Metal Working

BendersCNC Tube Benders/CNC Pipe BendersTube Benders/Pipe BendersRefurbished BendersBendPro MachinesPines Tube BendersVertical Tube BendersEnd FormingTube End Flaring & Beading MachinesTube End FinishersTube End FormersCrimping MachinesTube Branching & Collaring MachinesTube Closing MachinesMore Tube Forming & ResourcesTube Cut-OffsMuffler MachineryTube MillsTube Punching & Perforating MachinesTooling & Repair PartsTools & DownloadsView All Tube Forming -

Metal Working Machinery

AccessoriesAirMax Replacement BlowersAirMax Replacement FiltersTools & DownloadsBooth & Backdraft View All Dust CollectorsAdvantages & Disadvantages of Material Handling Fans for Dust Collectors

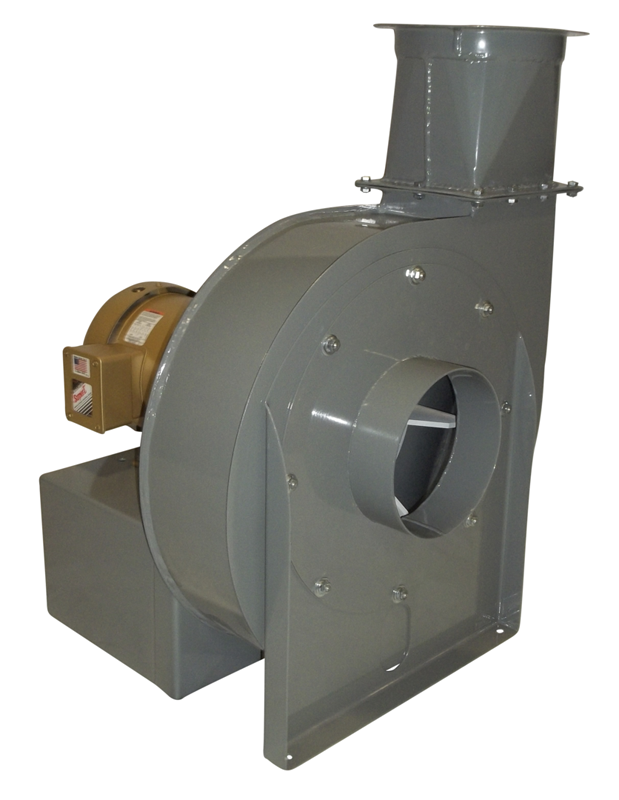

There are many types of fans to create air movement for dust collection systems, including material handling fans, backward inclined fans, and pressure type fans. What are both the pros and cons of material handling fans?

Material Handling Fans Capabilities:

Handles Abrasives: Material handling fans are built for heavy-duty applications and can be used to convey materials such as coal dust or saw dust. The flat, radial blade design of the wheel does not allow material from the airstream to accumulate.

Increased Static Pressure: Material handling fans are capable of increased static pressure, allowing the fan to move more air further while keeping the conveyed material in the air stream.

Less Bearing Wear: Because material handling fans spin slower, less bearing wear occurs while the fan is in motion. This makes the bearings last longer and help to keep maintenance to a minimum.

Why Aren’t All Fans Material Handling Fans?

Less Efficient: The wheels of material handling fans are less efficient as they require more horsepower per CFM than clean air fans.

Larger Footprint: Material handling fans take up more space than other fans.

Aggressive Use: The application of this fan conveying materials can sometimes cause uneven wear from abrasive or sticky dust, causing the fan to go out of balance and create destructive vibrations.

Contact AM Industrial Machinery today for expert advice on whether or not material handling fans are the best choice for your dust collection applications.

Home | Blog | About | Testimonials | Inventory | Export | Careers | Contact | AirMax | Login | Sitemap | Privacy Policy | Terms & Conditions | LocationAll Rights Reserved 2025, AM Industrial Group, LLC - Admin Login

Web Development by Alt Media Studios -

Tube Benders / Tube End Formers